Introduction

Learning the steps on how to print on textile should come after knowing the methods you can choose from. Fabric printing is always a reliable venture, whether as a hobby or a business. However, there are risks if you lack the knowledge of the methods to suit your printing needs.

So, before you get excited about exploring the world of fabric printing, tune in to this guide first. Below, we wrap up the most popular types of printing on fabric. This will guide you on the correct printing technique should you like to start or further grow your brand.

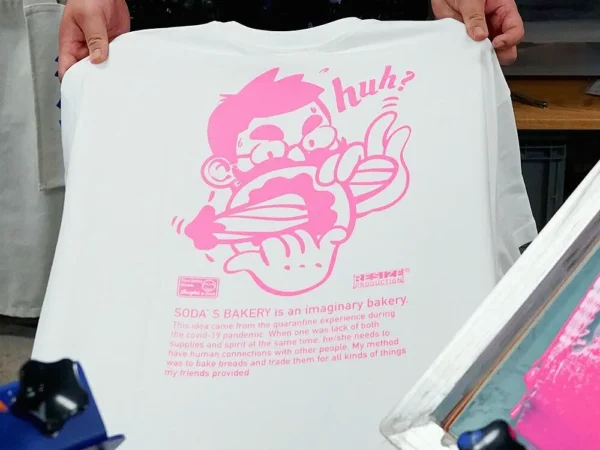

Screen Printing

Perhaps you have heard of screen printing before. That is very likely since it’s a household name in the printing industry. This technique from 1907 remains popular due to its inexpensive and versatile nature. Unlike modern printing methods, this technique employs manual craftsmanship for the most part.

Using this technique, you’ll need to create a stencil where your design template lies. The stencil contains impermeable and open areas, allowing the design to print onto the substrate. Such a template is made from a polyester mesh, where the ink or dye is applied by rolling over a squeegee. If you have a more complex print design, you’ll need several stencils for each design color. This means you’ll have to roll over your squeegee several times on separate stencils.

Screen printing is often used for printing designs that need a metallic finish. You can use its versatility on metals, vinyl, or fabric printing.

Pros:

- Prints on various substrate

- Durable finish

- Ideal for simple design

- Perfect for high-volume printing

Cons:

- Limited colors

- Requires longer set-up time

- Not ideal for low-volume printing

DTF (Direct to Fabric) Printing

DTF (Direct-to-film) printing is a modern and popular method. According to market insights, 67% of the US$2.6 billion digital textile printing industry is DTF-shared. Many regard DTF printing as a versatile and cost-effective cloth printing method. Hence, it’s the obvious go-to printing business model for small-time and beginner brands.

As the name suggests, DTF means printing your design on a transfer film first. You must apply a special adhesive powder to help the ink stick to the fabric more firmly. The powdered film will then need curing to melt the adhesive. Finally, you can put the film through a heat press flatbed to transfer the design onto the fabric.

The final output from a DTF printer will be accurate and vibrant. However, this method is less versatile than others when it comes to substrate options. DTF printing is limited to custom cloth printing, as it only works with soft substrates.

Pros:

- Versatile design customization

- Faster printing time

- Works with any colors

- Can print on natural and synthetic fabrics

- Low set-up cost

- Can print complex designs

- Durable transfer

Cons:

- Non-breathable prints

- Plasticised texture

- Design color may differ from the actual transfer

DTG (Direct to Garment) Printing

DTG printing is a product of continuous innovation in the printing tech industry. This relatively new method harnesses the printer technology’s full potential. Unlike DTF, direct-to-garment printing eliminates the need for transfer films. This method makes the process faster and more efficient by directly printing on the fabric.

DTG printing uses an inkjet printer to produce high-resolution transfers in minutes. Unlike other methods, the DTG printer does almost all the work. It does not need any pre-transfer to a special film. But, it needs pretreatment and a heat press to dry the ink.

Since DTG is digital printing, you must configure the digital file correctly. Make sure your digital format is compatible with the computer system. And that the colors and types of fabric are adequately specified.

One of the most practical advantages of DTG printing is that it caters to low—and high-volume print runs. Whether you are printing on a single shirt or a hundred shirts, the production costs remain minimal.

Pros:

- Vibrant prints

- High design customization

- Faster production

- Caters to small and large print runs

- Mostly automated production

Cons:

- Not ideal for dark-colored shirts

- Limited to cotton and cotton-blend clothes

Dye Sublimation Printing

Dye sublimation is one of the more popular printing techniques in textiles. The name comes from turning solid substances into gas without liquifying. When the ink is heated, it becomes gaseous and becomes solid as it is pressed onto the substrate.

This technique uses inkjet printers compatible with dispersed inks. Many accept dispersed ink as the best choice since it’s waterproof and long-lasting. Like other fabric printing methods, dye sublimation prints on film and uses a heat press for transfer. The design is often heat-pressed for around 40 seconds at 350-420 degrees Fahrenheit.

Most fabric printer businesses go for dye sublimation due to its durable finish. Since the ink is infused into the fabric, the print lasts longer as it solidifies. But, this fabric cloth printing also has its drawbacks. This technique is only ideal for polyester-based or spandex cloth. And unlike DTF, it is mainly limited to white or lighter-colored garments.

Pros:

- Durable prints

- Accurate colors

- Smoother print texture

- Cost-effective

Cons:

- Slower production process

- Limited to polyester and spandex garments

- Limited to a white or light-colored substrate

Digital Printing

Digital printing has been evolving fast. This innovative method relies on printing digital designs to various substrates. Unlike traditional methods, digital printing works with design software to print vivid images. This eliminates the need for manual and slow labor, thereby upsizing production.

Quality is also raised since the method allows for easy digital configuration. The prints become more accurate with proper color grading and material type matching. Many integrated printers also make the process smarter and more automated.

Like different methods of printing on fabric, digital printing has pros and cons. On the positive side, it offers high design personalization. Digital images are easy to edit through various digital design tools. Cost efficiency is also observed on short print runs with faster turnaround time.

However, the durability of digital prints is lower than that of offset printing. Despite the innovations, the longevity and strength of prints still need improvement. Also, digital printing remains limited to fewer fabric types.

Pros:

- Cost-effective

- Faster turnaround time

- High-resolution prints

Cons:

- Limited fabric types

- Less durable prints than traditional methods

Pigment Printing

Pigment printing has long been a renowned method in the textile industry. Its household status is due to its wide application and durable output.

Pigments are an insoluble substance that needs a binder to color textiles. They are particles that do not penetrate the fabric fibers but are durable enough to color textiles. When mixed with film-forming binders, pigments can color almost every fabric type.

Pigment printing can be applied through traditional or digital techniques. Today, pigment ink printing is often used in many digital printing techniques. Pigment inks are widely available and used in various coloring applications.

Pigment printing continues to be popular as it is inexpensive and very versatile. Pigment prints do not wash off easily and retain the vividness of colors for a long time.

Pros:

- Less expensive

- Widely applicable

- Resistant to wash-off

- Applicable to natural or synthetic fabrics

Cons:

- Requires binder

- Prints susceptible to crushing

- Not a very comfortable print texture

Which Printing Method Should You Choose?

Picking the correct printing method is not as easy as a “yes or no” question. It should hinge on calculated factors that suit your printing needs. Here are the careful considerations you must follow when choosing the suitable method.

Fabric

The fabric type you will work on has a lot to say. Remember that not all printing techniques work on every fabric type. You’d better go with dye sublimation if you specialize in synthetic fibers. Pick DTG printing if your canvas is cotton or other natural fibers. And choose screen printing should you want more versatility.

Design

Your design is also a decisive factor in your technique preference. If you are into vivid and complex designs, you should pick digital printing methods like DTF. These methods are better at producing accurate color matching, especially with multiple colors. DTF works with white ink, catering to the most complex designs.

Volume

Decide whether you’ll print short runs, high volumes, or both. If you are only a hobbyist, DTG is the right choice. Go with screen printing if you build a brand catering to larger orders.

Target Audience

If your market base is corporate, your designs will likely be minimalist and clean. Screen printing will be enough, as you’ll likely work with only a few colors. If you want to supply sports teams, dye sublimation is your best choice. Sports uniforms are synthetic fabrics; hence, they are a method specific to such material.

Conclusion

There are plenty of printing methods in the market today. Most of these popular techniques are the most competitive business model, too.

While some offer a better edge than others, they are not instantly the better choice. If you are looking for a suitable method, always balance the factors. In the printing industry, the perfect method exists if you understand what that technique brings.