Background and Importance of DTF Film

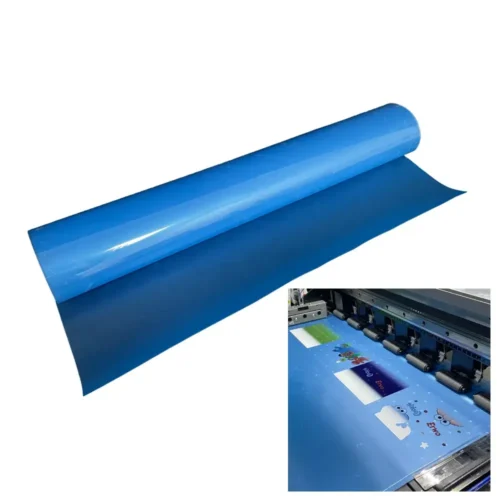

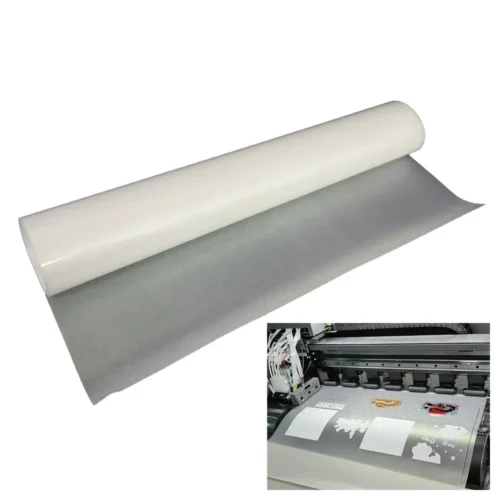

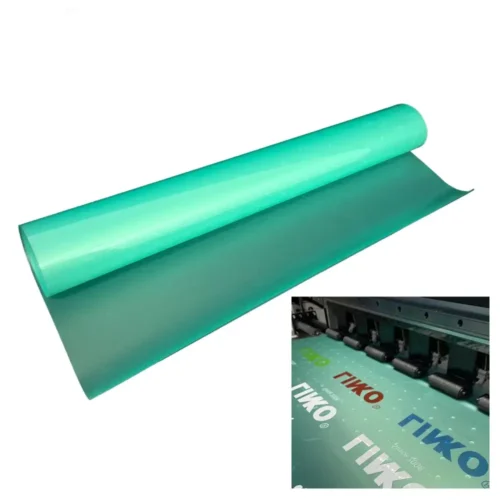

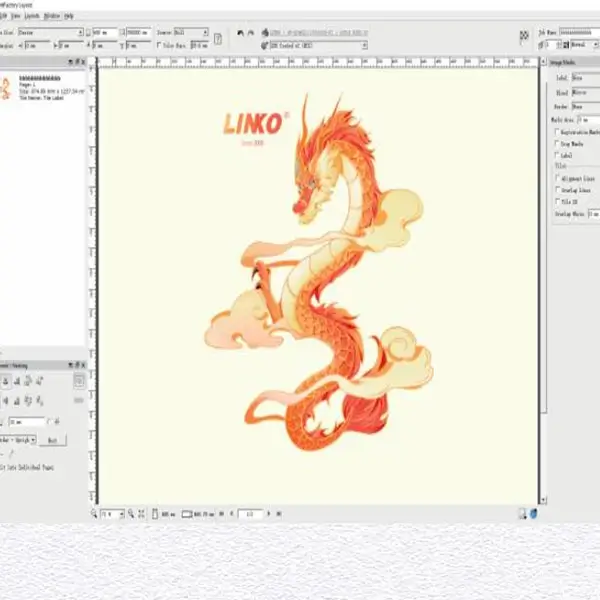

DTF Film is a key player in DTF (Direct-to-Film) printing solutions. It stands out for its superb smoothness, clearness, and how well it works with DTF printers.

It's not just great for producing high-quality images; it's also vital for being eco-friendly and sustainable.

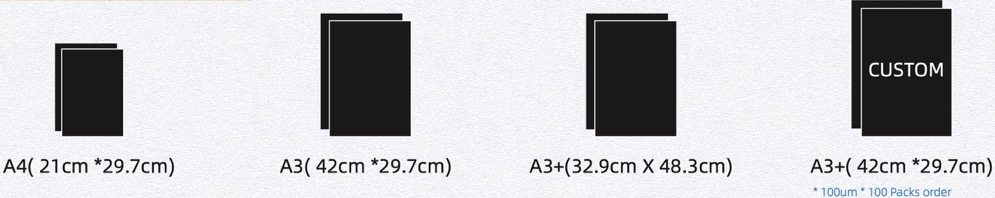

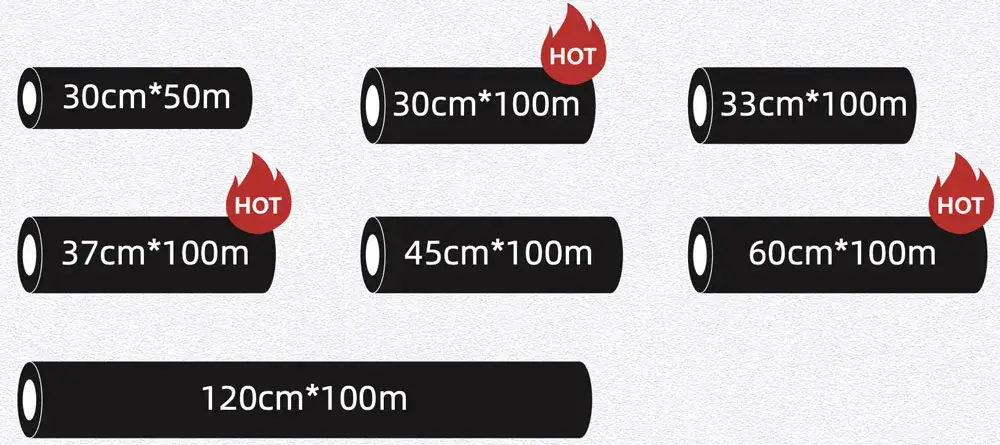

What is DTF Film?

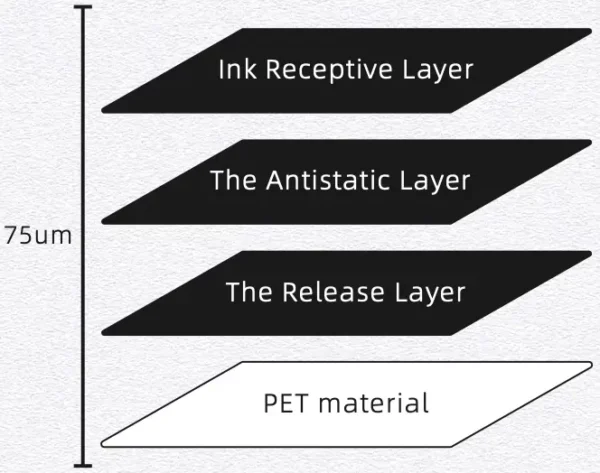

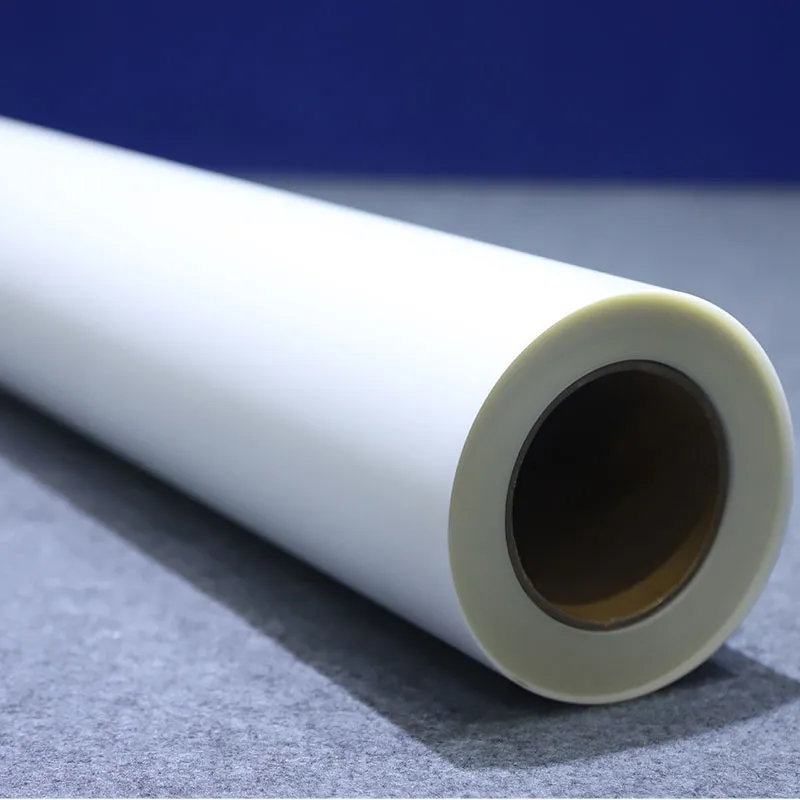

DTF Film is a special material made of PET film used for digital textile printing.

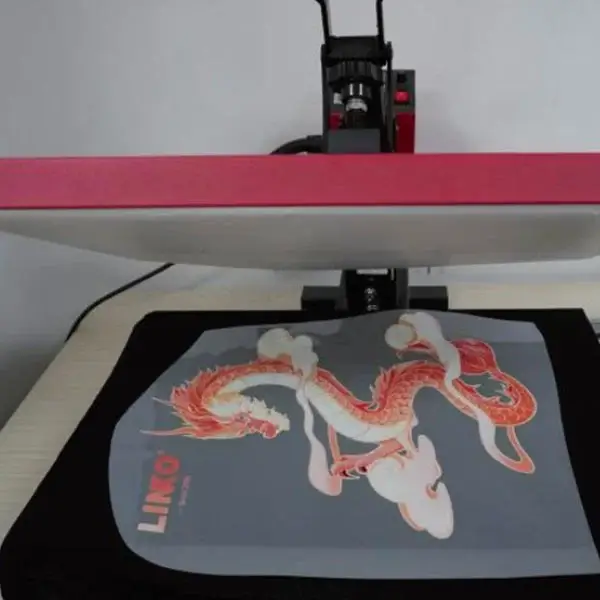

It is a key consumable for DTF (Direct-to-Film) printers. LINKO DTF Film prints the image onto the film. Then, it transfers the image to the fabric through heat pressing. This method gives high-quality, high-resolution prints.

This material is great for making top-notch prints. You can put them on various items, like T-shirts, hats, bags, and more. DTF Film is a major player in the world of digital textile printing.