Fabric designs are often made by using DTF printing and dye sublimation. Both have unique benefits and downsides. DTF does not need special materials like sublimation. Sublimation makes bright colors, but it’s best for polyester.

DTF prints are more flexible with different types of materials. Each way is suitable for various projects. As this post illustrates, the difference between sublimation and DTF. We will discuss the categories of items suitable for these methods.

What is DTF Printing?

DTF (direct-to-film), as it is also known, is ideal for printing fabrics. Using heat and pressure transfers patterns from a particular film. This method works with different fabrics. It is not limited to one material, allowing for various projects. DTF printing can achieve high-quality, precise results.

This versatility makes the design more creative and innovative. Designers and manufacturers can explore different fabrics. It’s a popular choice in the textile industry. DTF printing can make prints that look bright and last a long time.

How does DTF Printing Work?

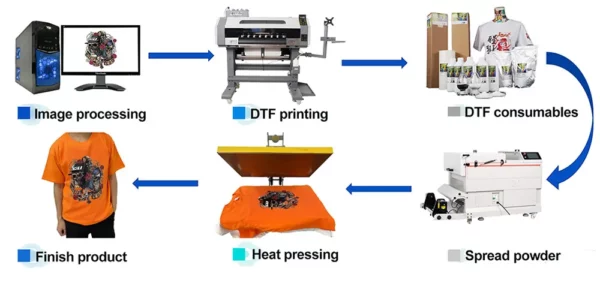

DTF printing starts with choosing the design for the project. Special inks will print the design on a unique, transparent film. The designer applies powdered glue across the design after publishing it. The design and glue on the film must dry before the adhesive can be set.

Next, place the film on the fabric and apply heat. The combination of heat and pressure transfers the design to the surface. Finally, someone removes the film, and the design stays on the fabric. This method makes designs look bright and detailed on different materials. Check out the ultimate guide to what DTF printing is and how it works.

What is Sublimation Printing?

Sublimation printing refers to printing designs on fabric and other materials. Printing a design onto special paper is the first step. The design is then put on the material, which is usually polyester. The heat creates a gas that bonds with the fabric’s fibers.

This method makes bright and clear pictures that can last a long time. People use it to make clothing, banners, and various promotional items. Sublimation is best performed on light or white backgrounds. This is to make sure the colors match precisely. The result is a durable, washable, high-quality print that stands out.

How does Sublimation Printing Work?

Sublimation printing means using dyes on special paper. This design prints on a coated object or polyester fabric. The ink transforms into a gas when heated and pressed. The gas ties the material together, ensuring the design’s enduring quality.

The material retains a vivid and sharp image. The colors are vibrant, and the print exhibits resistance to washing and dissolution. This technique is suitable for making custom textiles and promotional items. Sublimation is a solid and appropriate option for creating intricate designs.

DTF Printing vs. Sublimation Printing

Consider your project’s requirements when choosing between “DTF vs. sublimation” printing. The DTF excels in its versatility across various fabrics, not just synthetics. Sublimation printing is a great way to print on polyester-based items. DTF printing might be an excellent choice for projects that use many materials.

Want to know from “Sublimation vs. dtf” that sublimation is the best way to keep color and detail for a long time. Each method has its set of advantages tailored to specific outcomes. Your decision should match your project goals. You can use both techniques to solve problems. But what you select depends on the project’s material and how strong it needs to be.

Print Quality and Durability

The quality of a print determines how long it will last. DTF printing is straightforward and can stand up to washing well. Sublimation is exceptional at making bright and lasting colors that don’t fade. Both ways ensure good results for different projects. The way we make something affects its durability and appearance.

When appropriately applied, DTF printing and sublimation prints can last for many washes. Each method customizes various preservation needs and checks lasting designs. Selecting the right approach enhances the efficiency of printed materials.

Print Complexity

When choosing print complexity from “DTF vs. sublimation”, print complexity is different for DTF (direct to film) and sublimation techniques. DTF printing lets you design on various fabrics. Its processing process handles detailed prints with ease. Sublimation is superb at making complicated and bright pictures on suitable materials.

Both methods require meticulous preparation for intricate patterns. Query about “DTF vs. sublimation”: DTF and sublimation can support advanced projects. The choice of material depends on the effect you want. Complex designs must understand each method’s specifications. Performing tasks correctly ensures good results, no matter how difficult they are. Each printing method has its advantages for different designs that are more complicated.

Color Vibrancy

Bright colors are essential for printing materials that look good. Choosing from “DTF vs. Sublimation”, DTF printing delivers vibrant color options across various fabrics. This helps colors stand out, even on darker materials. Sublimation printing is excellent because it produces bright and lasting colors on polyester.

This method makes designs look bright and colorful. Both methods deliver vibrant colors that catch the eye. But, sublimation provides unmatched brightness on appropriate substrates. You base your choice on the materials you have and the colors you want. Vibrancy can affect how well your printed work looks.

Fabric Suitability

DTF printing works well on various materials. Material type does not limit it. DTF printing is great for many projects because users can easily change it. Sublimation, though, works best on polyester fabrics. The process uses ink to connect with the fabric’s fibers. This makes designs last a long time, but limits fabric choices.

It’s important to know what kind of fabric your project needs. It would be best to choose from “DTF vs. sublimation”, DTF for versatility or sublimation for polyester vibrancy. Each method serves different fabric needs, depending on the fabric. You should consider the fabric of your project to ensure optimal print results.

Products

We offer a variety of products catering to various project requirements. Each item in the collection is high quality. You can use them for work or at home. Our selection includes bright fabrics and durable promotional items for everyone. Advanced printing technologies make each product look good for a long time.

There are options for every creative try in our portfolio. Explore our collection to find the perfect match for your project. With innovation at the heart of our offerings, we expand our offerings. We will provide items that are better than you expected. They mix function with style.

- Apparel

In the world of customizing apparel, DTF printing and sublimation each have their perks. DTF printing blends style with advanced print tech. It ensures each garment makes a bold statement. Similarly, sublimation techniques bring vibrant designs to life. They turn garments into art you can wear. DTF printing focuses mainly on shirts. In contrast, sublimation works on various fabrics, opening up more creative options. Whether you go for DTF or sublimation, the key is quality and promising looks that last.

- Living & Home

When it comes to improving living spaces, both DTF and sublimation are great choices. In Living & Home, DTF printing adds comfort and style to items. It blends function and beauty well. Sublimation brings a subtle touch. It infuses decor and furnishings with vibrant colors and intricate designs. This enhances the ambiance of any room. DTF printing emphasizes handmade quality and durability. In contrast, sublimation widens customization. It lets people show their unique tastes through personalized home decor. Whether it’s cozy throws or eye-catching decor. Both DTF and sublimation let people create spaces that truly feel like home.

Quantity

DTF printing and sublimation are two popular methods for transferring designs onto fabric, each with its advantages. DTF printing offers bright colors on a wider range of fabrics. DTF Printing is known for handling large orders without sacrificing quality. The DTF process allows you to print a lot of film before moving it to different things.

Sublimation printing can make really bright and good prints, but it’s best for small to medium-sized batches. Heat and pressure are used to transfer an image onto a product. Sublimation is known for its durability and color accuracy. In short, DTF can be used for different sizes of orders, but sublimation is cheaper for large quantities.

Eco-Friendliness

It is essential to choose options for our planet’s future. We focus on reducing the environmental impact of our products. We select materials carefully. Not only that, but we ensure that they can reuse items and do not harm the environment.

Likewise, we design our manufacturing processes to reduce waste and conserve energy. By selecting environmentally friendly items, customers are supporting greener practices. We can work together to protect our environment. You can contribute to a more productive planet by picking our products.

Cost

When comparing DTF to sublimation, several factors influence the price difference. DTF’s complex process requires special equipment, raising production costs. Sublimation is more affordable with its simpler setup and materials. Yet, pricing is about more than just the method used. DTF focuses on quality and service, justifying its cost.

Each DTF product balances premium features with affordability. Strategic planning can reduce costs for any project. Understanding your needs allows DTF to offer budget-friendly, quality solutions. Choosing DTF means enjoying cost-effectiveness without compromising on excellence.

What Is DTF Printing Best For?

DTF printing is excellent for versatile textile projects. It works well with different fabrics, so it’s suitable for many other things. This method is good for businesses that print detailed designs on many things. DTF has unparalleled flexibility in custom apparel and accessories. Even on challenging materials, it ensures quality and durability. Choose DTF when you need high-quality and vibrant prints on diverse textiles.

What Is Sublimation Printing Best For?

Sublimation printing looks good on synthetic fabrics like polyester. This method is magnificent for sportswear and activewear because it is durable. It uses ink to make designs last longer without fading. Sublimation printing has bright colors and precise details.

It’s also helpful in making promotional products, like mugs and mouse pads. Sublimation printing is most effective for items that undergo frequent usage or washing. Using this method will give you clear and lasting results on excellent materials.

DTF Printing Vs. Sublimation: Which One Will You Choose?

Consider your project’s requirements when selecting “DTF vs. sublimation” printing. DTF is versatile across fabric types and can be used in many ways. Polyester is the best material for sublimation, offering vibrant, durable designs.

Each method has advantages, depending on the material and the end use. DTF is the perfect option for textile projects. However, sublimation is the best way to achieve high color fidelity in synthetic fabrics. Your choice is dependent on fabric preference and design requirements.