Introduction

A T-shirt business is one of the most profitable ventures you can start, even in your garage. But to do it right, you must know where to begin and what you need.

DTF printing is an excellent choice whether you are starting or have an established brand. You can create flexible designs and quality prints using a DTF printer. It is a cost-effective, easy-to-operate, and versatile business model.

Tune in to this guide to learn more about what DTF printing is all about. And grow your t-shirt printing brand in no time. Click here to learn how to print t-shirts at home.

What is DTF Printing?

DTF is an acronym for Direct To Film. This technique refers to printing the design on a film before transferring it to a fabric. You can transfer your preferred image to almost all fabric materials via a heat www.

Unlike other machines, a DTF printer can print in various colors since it works on white ink. The simplicity of the process and versatility of design make DTF printing popular. LINKO offers high-performance and low-cost DTF printers; click to view full models.

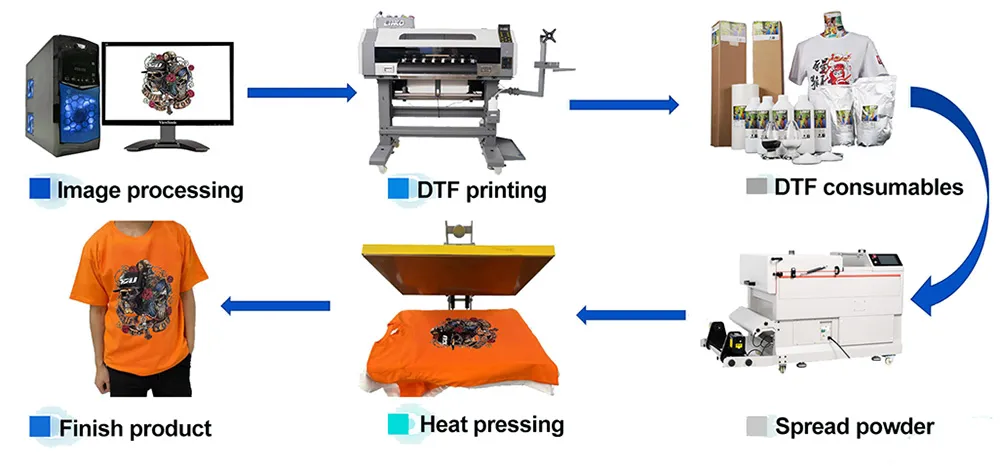

How Does DTF Printer Work?

Now that you know what DTF printing is, let’s familiarize ourselves with how the DTF printer functions. Many regard DTF printers for their versatility and ease of use. The printer produces high-quality DTF transfers and can handle various printing works.

For one, DTF transfers work on all kinds of fabric. It can also produce versatile designs from single-color shirt labels to full-size customs.

Here is how the DTF printer works:

1. Printing designs on PET film

Once your design is ready, the DTF printer does almost everything. Just send the file to the printer to start the printing process. Once set, the printer will transfer the design onto the PET film.

But make sure that your DTF printer is properly set up before printing. This means you load the film onto the tray and install the ink cartridges first.

Also, print your designs in white under the base before the multi-colored layers design. Without white ink, you’ll limit printing to white or light-colored garments only. White is the base for darker-colored fabrics to highlight your colorful design.

Finally, mirror your design before printing. You should invert your design in the file to avoid reversed DTF transfers. And don’t forget to save your design in an acceptable file format to be able to print.

2. Adding the colors

A DTF printer can work in different colors since it has several print heads. The first print head applies the CMYK color blends. At the same time, the second one is dedicated to applying the ideal amount of white as the base color.

The second head works accurately to ensure precise alignment of colors. This prevents the white ink from ruining the design and maintaining neat color edges.

Such crisp edges are one of the advantages of DTF transfers. They are hard to replicate or achieve using traditional screen printing.

3. Coating film with adhesive powder

This step is either done manually or automatically through the DTF printer. A DTF printer for beginners does not have an automatic powdering feature. This means you must apply the adhesive powder onto the film with your hands. Such a feature is more common to larger printers for industrial applications.

The printed film goes to a powdering unit in some printers with this feature. It is then evenly spread with adhesive powder while the film is wet. The combination of the ink and adhesive powder results in the soft touch that DTF transfers give.

After the powder application, the film goes into an automatic shaker to remove the excess powder. It then passes on a drier belt to melt and cure the adhesive, ensuring it is glued on the ink.

4. Heat Pressing

The last major stage would be the heat www. After the film is printed on, powdered, and cured, it is ready for transfer to the fabric.

The transfer process should be quick since a heat press machine uses high pressure and heat. Usually, you would only need 15-20 seconds in the heat press at around 160-170 degrees Celcius.

You would need 10-15 seconds of pressing the film onto the shirt to transfer the design. Then, you can peel off the transfer film and place a finishing sheet onto the shirt. Press for another 5 seconds to secure the ink onto the fabric further.

Others prefer covering the DTF transfers with an extra film layer for protection. Applying a Teflon sheet, for instance, gives added protection and a gloss finish.

What Do I Need to Print DTF Transfers?

There are many choices if you are looking for the best DTF printer for small business. You can use DTF printing to start or expand your brand.

Here are the answers to your “What do you need for DTF printing” question.

DTF Printer

You may think you’ll strictly need a specific printer type for DTF printing. But this is not the case. A usual desktop inkjet printer will suffice for the job.

However, you have to go with a 6-ink tank printer to accommodate the required colors for printing. The standard DTF printer ink can go into the CMYK tanks, while the LM and LC tanks can store the white ink.

But you can also purchase DTF-modified printers from a reliable DTF printer supplier. If your business operates on high-volume printing, buy an automatic DTF printer. This printer type guarantees high quality, cost-efficiency, and speed in printing.

A manual DTF printer is also available. This reliable equipment lets you print on any surface. But it will need a separate curing oven and heat press machine, unlike an automatic printer.

Even so, manual DTF printers can be the cheapest DTF printer in the market to help you start your business. You must find the best direct-to-film printer to guarantee quality prints.

Consumable Materials

You will also need consumable materials to do DTF prints. These are the supplies that are only used one time. And which needs restocking more often.

DTF PET films are special transfer films. They are different from transfer films used in screen printing methods. They come around with a thickness of 0.75 mm and are available through cut sheets for smaller printing applications. But you can also buy them in rolls for larger commercial use. Another characteristic is that they can be cold-peel or hot-peel type of films.

Remember that transfer films cannot be reused. Once made to transfer a design, it loses its printing and transfer features due to exposure to heat. After using one, put them straight into the bin and restock regularly.

A DTF printer ink is a special pigment ink that is available in colors: black, yellow, cyan, magenta, and white. The white ink is required as a base and foundation for multi-color design layers. You would always want to have ample stock of ink refills since they will need restocking more often.

DTF adhesive powder is required to bind the ink pigments to the fabric fibers. Not all adhesive powders are of the same grade. You must know what grade you need for every printing configuration.

- DTF Printer Software

DTF printer software is a crucial ingredient in DTF printing. This special RIP or Raster Imaging Processor software can handle white and CMYK colors. DTF software influences the overall print performance of a DTF printer. It governs the ink levels and characteristics, drop sizes, and color profiling for an optimized quality of transfers.

A heat press machine serves one main purpose. That is to transfer the printed design from the film onto the fabric using pressure and high heat. But, without a curing oven, it can also melt the adhesive powder. Others would also preheat shirts in this machine to remove any trace of moisture from the fabric that can compromise the print quality.

This machine handles the application of DTF transfer powder onto the PET film. However, you can still proceed with your transfers without this machine. This is unnecessary, as you can still manually apply the DTF powder onto the film.

The curing oven melts the adhesive powder to bind with the ink pigments. But, if you don’t have one, you can use your heat press machine for such a function.

How Much Does DTF Equipment Cost?

After knowing what a DTF printer is, let’s learn how much it costs.

Calculating the equipment prices for DTF printing can be tricky. Different factors are to consider, such as the specs, capacity, type, and even equipment brand. But if you are to look at the budget-friendly converted DTF printers, you can expect to pay from $500 to $1000.

A bundle offer will even land you more savings. You can find a package including a printer and heat press machine, with few consumable supplies for under $2000.

But if you can pay more for a more reliable machine, you can opt for a dedicated transfer printer for shirts. A dedicated DTF printer will cost you starting from $3000 and up. But then again, finding a bundled package will be the smart choice to lower your purchase cost.

If you are ready to upgrade to a mid-range DTF printer with more advanced features and integrated equipment, a minimum of $9000 will do.

Before purchasing, It is better to look for a quote online and compare the best prices of your needed equipment.

Pros and Cons of Printer DTF

While a DTF printer remains a go-to for many small to large printing businesses, it is not without its advantages and disadvantages. Below are its pros and cons.

Pros:

- Versatile, can work with any fabric

- Provides soft-touch feel print quality

- Pre-treatment isn’t required

- Easy to operate

- The printing process is faster and simpler than other printing methods

- The printed shirt demonstrates good wash resistance

Cons:

- Color vibrancy can be less compared to that of sublimation printing

- DTF transfers give a plasticized feel

Differences Between DTF, DTG, and Sublimation

DTG( Direct To Garment ) printing and Sublimation printing are also two of the most common methods in the printing business. Just like DTF, they have notable advantages and disadvantages over one another.

Here are the main differences between these three:

- Fabric type

As we know it, DTF transfers work on any type of fabric. On the other hand, DTG printing is best suited for cotton, while sublimation is for polyester.

- Fabric color

DTF transfers can maintain good color vibrancy on any fabric color. DTG is more suited to dark or black, and sublimation is for lighter or white fabrics.

- Print texture

DTF transfers exhibit a smoother and more plasticized texture on shirts. DTG feels rough, while sublimation feels as if there are no prints on the garment

In terms of process, DTG prints directly onto the shirt but requires pretreatment of the garment for proper image transfer. Compared to DTF and sublimation, it does not require any transfer paper.

In sublimation, a transfer paper is involved, and heat is required to transfer the design. But unlike in DTF, sublimation does not use liquid ink but a solid state ink that binds with the fabric using heat.

Conclusion

Now that you have learned the meaning of DTF transfer, its process, and its cost, you can confidently plan your next big business move.

Remember that the DTF printing business is one of the most common printing methods for a reason. It is versatile, cost-efficient, easy to operate, and has a faster return on investment.

Start crafting your brand today and be the next big name in the world of DTF printing. If you want to inquire about the DTF printing business, please contact the LINKO team, who will serve you one-on-one.