Sublimation printing is an emerging printing process for printing patterns on various materials, or on fabrics consisting of not less than 90% polyester. The main principle is the chemical reaction between ink and fabric under high temperature and high pressure, which is widely used in clothing (sportswear, women’s clothing, etc.), home textiles (curtains, blankets), etc. Polyester fabric is one of the most widely-used fabrics besides cotton, with low cost and good hand feeling, and can be mass-produced at high speed.

Principle

The principle is to print the color pattern on special coated sublimation paper in advance, and then use roller transfer machine to transfer it to fabric by hot stamping. Also, it can be transferred to the surface of other objects with special coating.

Applicable materials: polyester and other garments with more than 80% of chemical fibers.

Sublimation is widely used in

- Apparel Industry, such as sportswear, dresses, swimwear, advertising Shirts, cycling wear, etc.

- Home textiles, curtains, blankets, sheets and quilts, national flags, etc.

- Customized gift, such as cups, bowls, porcelain plates, etc.

The whole package includes a sublimation printer, roller transfer machine, sublimation ink, and sublimation paper.

Now, please let me introduce the features of this product.

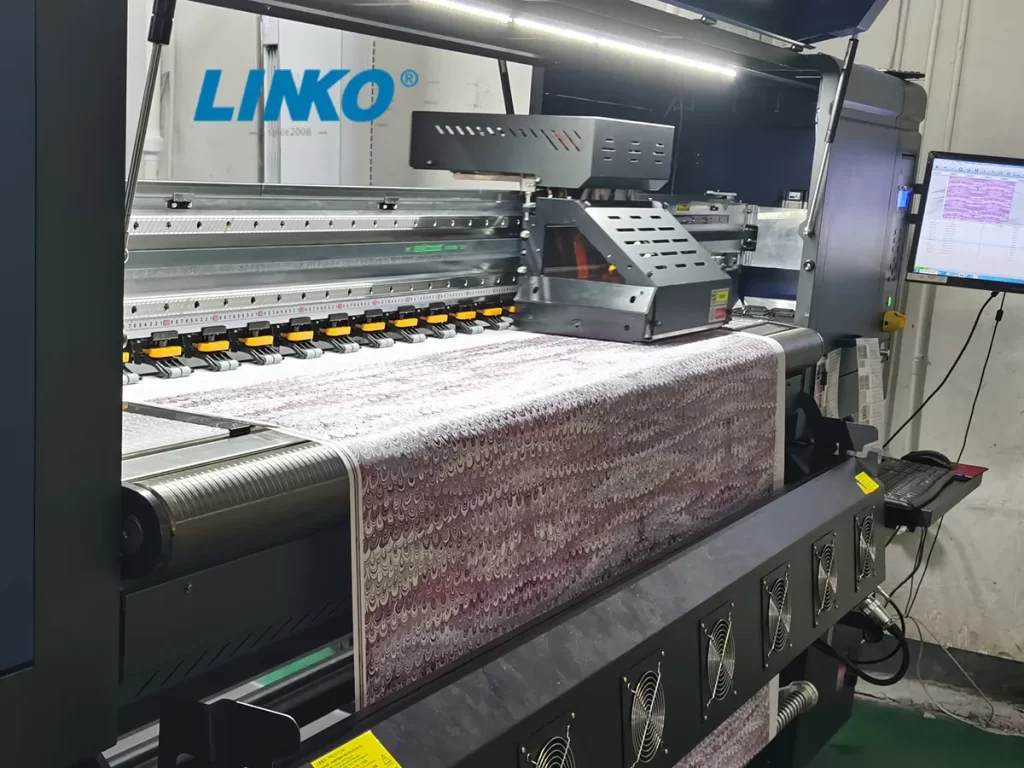

- Advantages of LINKO sublimation printers:

- The machine is equipped with a self-cleaning device that has one-way valve to increase the stability of the ink circuit;

- Built-in heating and stable fans;

- High-quality DC servo motors have good stability and long service life;

- The three-roller structure has more stable and accurate paper feeding.

- LINKO Sublimation ink

2.1 Compatible printer

- Epson I3200 print head 1/2/3/head printer, suitable for start-ups, the monthly output is less than 2000 pieces of jersey, 8/15 heads are suitable for mass production, the monthly output is higher than 60,000-80,000 meters.

- Epson S3200 Industrial Head Printer

- Kyocera Industrial Print Head

2.2 Ink density level

- Normal density ink, suitable for I3200 print head

- High-density ink, suitable for S3200 and Kyocera industrial heads

- Ultra-high density ink, suitable for industrial heads and ultra-thin paper

2.3 Advantages of our sublimation ink

- LINKO sublimation ink density is higher than the market – C: 0.15% Y: 0.15% M: 0.25% K: 0.35%

- Ultra-high density ink can use ultra-thin heat transfer paper, down to 28gsm

C.We have acquired authoritative certificates in the ink industry such as OEKO-TEX/CE/RoHS/REACH.

- Bright color, high color fastness, and good fluency

- Sublimation Paper

The printer uses paper with 31-100G gram, and its transfer rate is as high as 95%.

- Roller heater

The roller heater is the most widely-used solution for transferring in the market. It lowers labor cost, with the advantages of high transfer speed, simple maintenance, clear transfer and well-distributed heating. Our roller heaters also have a blanket adjusting device, which does not require manual adjustment. This will prevent the blanket from being burned due to long-term contact with the drum. Our rollers are chrome-plated, high hardness, wear-resistant and non-stick. They also have electronic control panel that has temperature control and motor control, which will help easily adjust temperature and speed.

We provide one-stop sublimation printing solution service

- We provide all supporting solutions, with continuous and strict product testing, to ensure the stability and compatibility of printing, and that any product problems can be traced to the source.

- We offer one on one technical service, after-sales guarantee, and thorough guidance to help customers to use our equipment with zero experience.