Introduction

T-shirts are a basic necessity for many and an art for some. You will likely want to make your own shirts at home to express your style better. But besides their artistic relevance, t-shirts are also a great business opportunity.

Learning how to make shirts should be easy. You can choose from different methods such as DTG, DTF, or embroidery. It’s achievable if you have the resources and knowledge to do it.

Thankfully, this guide is your starting point for printing t-shirts at home. We detail the advantages and disadvantages of 5 types of T-shirt printing machines. Help you choose the best home T-shirt printer for beginners!

5 Ways to Print T-Shirts at Home

T-shirt printing is a versatile work as it offers broad customization. Besides limitless design ideas, several printing methods can fit your needs. Some methods are perfect for every type of garment and print volume. Let’s discuss them one by one.

1. Direct-To-Garment Printing

DTG printing is a revolutionary and popular method for tee printing. As the name suggests, it’s a method where the ink is directly sprayed or printed onto the garment. It produces high-resolution digital prints within minutes using specialized inkjet technology.

Knowing how to make shirts using DTG printing is straightforward. You can choose your design and let the printer do most of the work. Unlike other methods, DTG does not include pre-printing your design on a transfer film. But, it still requires pretreatment before printing. So you’ll have to make room for a pretreatment machine and a heat press to cure the ink on the garment.

However, the downside of DTG printing is that it is specific to natural fabrics like cotton or bamboo. Setting up for DTG printing can also be expensive. But second-hand and cheap DTG printing machines can still give you awesome prints.

2. Direct-To-Film Printing

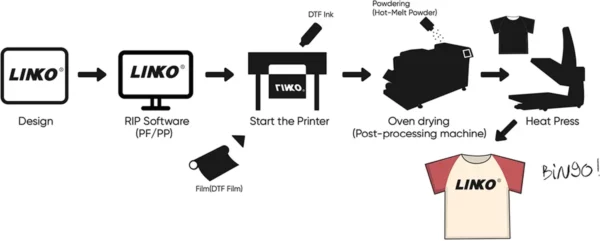

DTF printing works differently from DTG printing. It prints the image on a thin transfer paper before pressing it on the shirt. You must apply a special adhesive powder on the film while the ink is wet. Knowing how to make shirts using DTF is less tedious as it does not involve pretreatment.

DTF can be a good starting venture for beginners learning how to make shirts on their own. DTF prints are versatile since they work on almost every fabric type. The designs are also flexible by handling many colors and working with white ink. This results in crisp, vibrant, and high-quality design transfers.

But like any other method, DTF printing also has some caveats. This comes in the form of a plasticized feel of the printed surface. And the prints are not as breathable as DTG transfers. Even so, the DTF printer is a great choice for making your own t-shirt at home. The entire series of LINKO DTF printers is suitable for home T-shirt printing. The two most popular home t-shirt printer models are DTFLINKO B8048 and DTFLINKO B602.

3. Dye Sublimation

Dye sublimation also uses heat and pressure to transfer designs onto a tee. You’ll need a sublimation printer, sublimation paper and inks, and a heat press to carry this out. Higher temperature evaporates the special inks and bond them to the fabric. This makes an inseparable transfer and the most durable print you can have.

But sublimation only works for super-specific shirts made from pure polyester. It’s because sublimation uses higher heat that natural fabrics can’t handle. Also, it is exclusive to white or light-colored shirts. Still, dye sublimation is an easy way to learn how to make shirts if you’re a beginner.

Once you master making your own T-shirt at home, you can transition to higher-volume printing. Dye sublimation is ideal for small to large printing as it finishes a shirt in short minutes.

4. Embroidery

T-shirt printing only sometimes needs ink to stand out. This is the case for embroidery, a mainstay in the t-shirt printing business. Embroidery creates cool designs on many fabric types and has excellent durability.

But you don’t have to know how to stitch your design by hand since this method is all automated now. You can have yourself an embroidery machine that creates design at extreme speed. Embroidery lets you create a relaxed and minimal style. This is an excellent alternative for those who find beauty in simple prints.

Some complex designs will take longer and cost more. The materials for embroidery are more expensive than those used for digital printing methods.

5. Screen Printing

You cannot know how to make your own T-shirt without knowing what screen printing is. This traditional way of printing t-shirts remains as effective as it first came out. Screen printing or silk screening uses thicker ink to transfer graphics on shirts.

It involves a fine mesh screen that holds the stencil to create specific designs. Complex designs will need a few squeezes and successive use of different stencils.

A squeegee runs over the ink on the mesh to transfer the design. The ink transfer remains a manual labor, but cutting the design can be machine processed.

Its advantages include durable prints, flexible material choice, and high-volume printing. But, it’s more tedious than other methods and requires a larger workspace.

What do I need to Print T-shirts at Home?

The resources you’ll need to make your own shirts at home will depend on your chosen method. Yet, some materials and equipment across different methods overlap with one another. In the end, we recommend you start with DTF printing as your method of choice. Below are the basic supplies you’ll need.

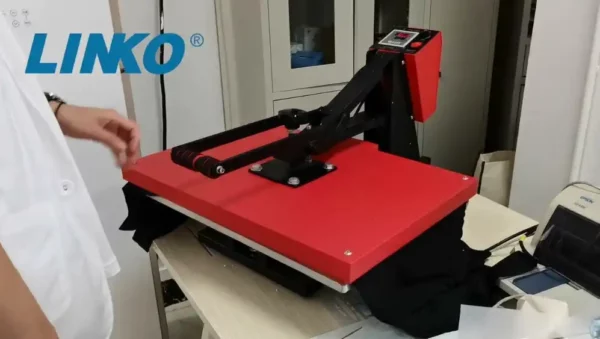

A Heat Press Machine

This is an everyday necessity in t-shirt printing. A heat press machine can be used for design transfer, pretreatment, or curing. In DTF printing, its primary purpose is to press the design from the film to the fabric. But it can also preheat shirts to remove moisture before printing on them. You can also use it to melt the adhesive powder without a designated curing oven.

A DTF Printer

A usual inkjet printer with six ink tanks is enough to do the job. The standard ink colors can go to the CMYK containers, while the white ink goes to the LM/LC tanks. You can start with a standard printer since you’re still learning how to print t-shirts at home.

You can now look up converted or used DTF printers on the market. They can cost around 500 to 1000 dollars. You can also go for bundled offers at below $2000. Bundle offers will include some consumable supplies to help you start printing. I recommend two small printers: Linko L402 and Linko A602. For details, please click here.

Once you transition to bulk printing, you can consider buying a more advanced DTF printer. It’s an automatic machine integrated with powder application and curing features. But make no mistake, these machines come with hefty price tags. It depends on your business needs. Contact the LINKO team to help you choose the DTF printer that best suits your business.

DTF Ink

DTF inks are special pigmented inks. It varies from sublimation ink, and alternating it for DTF ink could clog or damage your DTF printer. DTF inks are specific to this method to ensure particular DTF transfer quality.

It’s vital that you maintain enough ink supply and should restock regularly. It’s one of the fastest-depleting consumable supplies, so guarantee you’re always on stock.

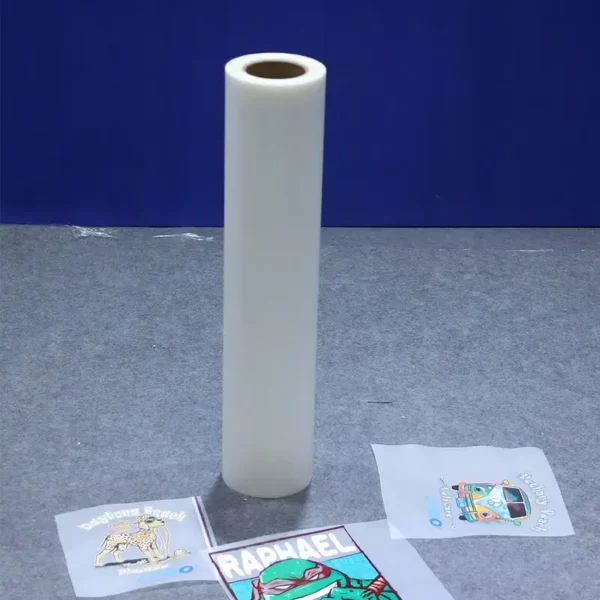

Transfer Film

DTF transfer films may come in rolled or cut sheets. These are unique PET films with 0.75 mm thickness and can be hot-peeled or cold-peeled. They are disposable films that are not reusable. You can only print on them once.

DTF Transfer Powder

A DTF transfer powder is a hot melt white adhesive powder. You apply it on transfer films while the ink is still wet. This process ensures that the ink pigment binds to the fabric fibers after transfer.

You either apply them by hand or through an automatic powder shaker. Next, the powdered film goes through a curing process. And then heat pressed on the shirt.

Aside from the consumable supplies, you would also need these equipment and materials:

- Desktop/ laptop

- DTF design software

- Curing oven

- Automatic powder shaker

- Shirts

How to Print T-shirts at Home: Tips to Consider

Knowing how to make T-shirts at home needs careful planning and preparation. Without these, it’ll be more challenging to execute or is bound to fail. But don’t worry! We round up some tips you could consider to make your t-shirt printing quest without a hunch.

- Use quality materials

Before anything else, try investing in quality supplies and equipment. Don’t consider quality an unnecessary added cost but a wise investment. The market competition for printed tees is tight. And sometimes, the customer preference can boil down to the print and shirt quality.

Quality should be a top consideration even when printing a t-shirt for yourself. Nothing beats using a quality product, especially if you made it yourself.

- Consider market trends

Try looking at what’s new and hot. This should give you an idea of what type of prints to go after and the method to use. Whether as a hobby or business, T-shirt printing should depend on current trends. After all, it wouldn’t be nice if you print and wear outdated graphics style.

- Practice before executing

Practice makes perfect. Or at least it prevents you from making costly mistakes. Before transferring your designs to the shirt, practice printing on scratch first. It helps make adjustments if there are design or equipment settings errors. Also, practice helps with mastering your skills.

How to Start T-shirt Printing Business at Home?

The t-shirt industry is a competitive place. Competitors will leave you hanging if you lack robust marketing strategies. Consider these marketing tips below to help you excel or stay afloat. Here is more guidance for small businesses on starting a DTF printer business.

- Choose your target audience. Knowing your customer base helps identify the best business model. It’ll help you identify the suitable printing method, design ideas, and brand to build upon.

- Raise brand awareness. A compelling brand story isn’t enough to win customers. You must continue to raise your brand’s visibility to generate leads and sales. Social media platforms are a strong start and focus on your brand awareness campaign.

- Maintain brand visibility. Create and promote your business through a healthy website or page. You can upload regular content that hooks your target audience. Improve your marketing further through emails, blogs, and other copies.

- Build excellent customer service. A good business doesn’t stop at producing quality products or services. It extends to how you handle feedback or engagement of customers post-selling. Make sure you attend to every concern that your customers have. Building a good reputation is an equally excellent marketing opportunity.

FAQs about Print T-shirts at Home

Q1: What do I need to start t-shirt printing at home?

You’ll need different supplies and materials depending on your preferred printing method. In general, you will need a printer, a heat press machine, a workspace, inks, transfer paper, and shirts.

Q2: What is the Best Way to print on t-shirts at home?

While it is a matter of preference, we would recommend DTF printing. DTF transfers are versatile as they apply to different fabrics and many colors. They also produce vibrant and crisp print details. Not to mention, they are easier to set up.

Q3: What is the cheapest method of printing shirts?

Screen printing is a very cost-efficient method. It doesn’t need the same energy consumption as other methods, as the transfer can be made entirely by hand. With screen printing, you can create and cut the design by hand and squeeze the ink also by hand.

Q4: Can you make money by making T-shirts at home?

Yes, you can definitely make a profit from printing shirts at home. T-shirt printing is one of the businesses that has a quick return on investment. It also has a higher profit margin.

Conclusion

T-shirt printing at home is an excellent investment, proven by many. The industry continues growing, but it’s not too late to hop on the trend.

But before you start, weigh which method and business model suits you. T-shirt printing wouldn’t be as hard if you are well aware of the path you’ll take. Consider your budget and try starting with what you can; after all, it’s a scalable business.