Introduction

In this vibrant world of printing technologies, innovation reshapes creative possibilities in one way or another. Modern printing methods guarantee deep and long-lasting designs.

Advanced technologies enhance the color intensity and brilliance. Two notable methods – DTG (Direct-to-Garment) and DTF (Direct-to-Film) are most important in this regard. Both of these modern techniques ensure that printed materials, ranging from garments to items, maintain their brilliance and meet the demands of users.

DTF printing is an innovative way to use specialized film and heat transfer processes to create attractive designs on garments. This method uses UV-curable inks or an eco-solvent to print designs onto a film. It then employs pressure and heat to transfer these designs onto a fabric.

While navigating the world of printing methods, longevity and brilliance are a must. DTG is famous for its lively color reproduction of garments. This makes each of them a formidable contender.

So, a detailed examination of their features and benefits is important to find the superior method. This article will give you better insights into the features and help you select the best-suited printing method for your needs. Let’s take a detailed look at both technologies, DTF printing, and DTG printing, and see which one stands tall.

What is DTF Printing?

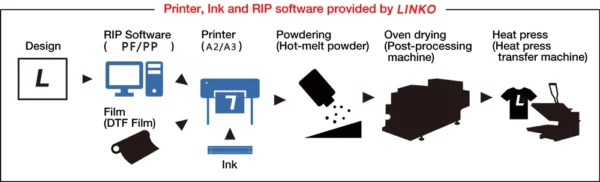

DTF printing is a garment printing technique that has evolved rapidly in recent times. It has revolutionized transferring designs onto fabrics with unmatched vibrancy and precision. Its long-lasting designs differentiate it from other conventional printing methods. Behind the scenes, DTF involves a unique process. It uses different kinds of inks and solvents to craft intricate patterns, fine details, and vibrant colors on specialized films.

For this initial stage, a separate film comes into play, which ensures precise replication of the desired design with utmost brilliance. After the printing phase, the process transfers these remarkable designs onto the fabric surfaces. This part requires the use of a pressure and heat application mechanism, which is a fundamental step in binding the design.

What comes out as a result? It is a wonderful fusion of artwork and lively colors embedded into a fabric that ensures durability. One of the aspects that sets DTF apart from DTG vs. DTF is its versatility. This method doesn’t limit itself to conventional boundaries, which is true with direct-to-film or other printing methods.

The former offers the flexibility to embellish different materials with attractive designs. All in all, DTF printing is a unique method with many differences from conventional printing solutions.

How Does DTF Printer Work?

In terms of fabric customization, DTF Printing has a vital role to play. Its divergence from traditional methods to introduce an entirely different yet remarkable design makes it unique. Let’s see the simple yet essential steps involved in this process:

Design Preparation

Ensure your design is ready to be imprinted on the special transparent film.

Adhesive Film Application

Apply adhesive film on a transparent film. This adhesive film will later carry the design to be printed.

DTF Printing Process

Then, a DTF printer prints the design directly onto the adhesive-coated film. DTF inks are specially designed to carry out this process.

Drying the Printed Film

Allow the printed film to dry completely to avoid smudging or color bleeding during the transfer.

Film Placement on Target Material

After the film is completely dried, place the film onto the target material, such as fabric or garments, with the printed side facing toward the design film.

Heat and Pressure Application

After correctly placing the film on the desired material, apply heat and pressure using a heat press machine. The heat activates the adhesive film, transferring the design from the film to the garment or desired material.

Film Removal and Inspection

After heat pressing, carefully remove the original film from the material with the design printed on the material.

What is DTG Printer?

Direct-to-garment printing, or simply DTG printing, has proved to be a game-changer in apparel customization. It employs specialized DTG printers to transfer designs directly onto the fabric surface. This process is different from heat press and screen-printing techniques.

It involves a digital printing process that prints the design onto the fabric without using separate films. The method also involves the use of a particular DTG machine or an inkjet printer to get the printing job done. DTG printing isn’t a bad option for on-demand printing requirements and offers flexibility for small-batch printing.

And if you require custom garments, you can rely on it because of its versatility and “no compromise on quality” feature. So, the end product you’re getting will be good enough to last long.

How Does DTG Printing Work?

Direct-to-garment printing, often referred to as DTG printing, involves the utilization of a specialized printer known as a DTG machine. This method stands out for its ability to apply designs directly onto the surfaces of garments, offering a unique and efficient approach to apparel customization.

Digital Design Creation

Create e a design. This design is based on intricate patterns and details, which are imprinted on the fabric.

Fabric Preparation

After this, the digital design will be ready. Then, the fabric passes through the printing phase. In this step, the design transfers to the fabric or garment.

Inkjet Printing with Textile-Grade Inks

The heart of DTG printing lies in the inkjet printer equipped with textile-grade inks. This printer transfers the design onto the fabric’s surface with accuracy.

Optional Ink Curing

After this, there’s an option to cure the applied ink to increase the durability of the print. The absence of heat or pressure during this process secures the texture of the fabric.

Handling Complex Designs

DTG printing is excellent in its capacity. So, it can handle complex designs effortlessly, such as multicolor patterns or high-resolution images. The DTG machine executes all details with accuracy. This makes the method particularly suitable for designs requiring a high level of color accuracy.

Versatility for Small-Scale Printing

DTG printing is equally beneficial for small-scale printing requirements. Its adaptability makes for custom-designed garments. So, it ensures the quality of prints meets the desired standards.

DTG vs DTF Printing: What are the Differences?

Both the printing methods look pretty similar to each other. But there are some differences between them. Though both of these provide exceptional results, let’s see how they’re different from each other.

Print Quality and Durability

DTF offers remarkable color accuracy combined with details, and its prints are elastic and durable. It is resistant to fading and cracking but may produce cracks if used in hot water for a long time. On the other hand, DTG offers full-color prints that are durable, soft, and breathable. Fresh prints are not that soft; however, after a few washes, they become smooth.

These prints are also resilient to fading and cracking. But ensure you have the best cheap DTF printer to get it done.

Print Complexity

The greater the print complexity, the better the design. DTF prints have unparalleled print complexity, with full-color designs, small texts, and fine art. The print looks so realistic and sharp even after being printed on a separate film before becoming a part of the fabric.

On the other hand, DTG supports photos, graphics, and colorful designs, but due to fabric absorption, it is not an excellent option for intricate designs. So, it doesn’t matter if you’re using a cheap DTG printer or any other one; its limitations will be there.

Fabric Suitability

DTF is adaptable to materials such as nylon, cotton, polyester, etc. The best part is that the print quality remains the same. At the same time, DTG is a good option for natural fabrics, like bamboo, cotton, and their blends. Natural fibers are used here because they bond better with the ink. So, the main difference between DTG and DTF is their bond formation with ink.

Eco-Friendliness

The direct-to-film prints involve the use of water-based solvents and minimize waste to a large extent. This means they align well with sustainability goals. In comparison, DTG reduces overproduction because of on-demand production only. Some machines produce almost no wastewater.

Color Vibrancy

DTF uses white ink as a base and then the primary colors. As a result, you constantly receive vibrant prints without fabric type or color. At the same time, DTG uses CMYK colors except for colorful or black garments. For them, white base ink is used. This slightly affects the brightness of the print compared to DTF. Even the best cheap DTF printer gets it done better than DTG.

On-Demand Fulfilment

Both printing methods fulfill on-demand order requirements but only allow for single-cost item orders. This is an ideal option for e-commerce and drop-shipping models.

So, the difference between DTG and DTF isn’t that much, particularly when you talk about their production and specifications. But both have their way of implementing the design, making each unique.

How to Choose Between DTF and DTG?

DTF vs DTG, the selection between both printing methods depends on various parameters ranging from specific needs and preferences.

DTF stands out for its remarkable color accuracy when considering print quality and durability. DTF ensures elastic and durable prints that resist fading and cracking.

On the other hand, DTG offers full-color prints that are unique and soft. These prints obtained from DTG become even smoother after a few washes. Both DTF and DTG are better and provide excellent results.

But again, the choice depends on the desired quality and longevity of the prints. Print complexity is another crucial factor to consider during the selection process.

DTF stands out in intricate designs with full-color details and small texts. DTF also excels in fine art, maintaining realism and sharpness even after the design is printed on a separate film.

In contrast, DTG supports photos, graphics, and colorful designs but may face limitations in handling highly complex patterns due to fabric absorption. Color vibrancy and effectiveness are other considerations in the selection process.

DTF delivers constant color flow and brilliance across different fabrics. On the other hand, DTG uses white base ink for specific garments, which may slightly affect brightness compared to DTF.

One of the reasons why industries and business owners prefer either of them is high print quality. They’ve to compromise over it using other methods. So, either DTG or DTF printing becomes an automatic choice.

Conclusion

The modern world belongs to garment printing, and there’s no doubt about it. But you must choose between DTG and DTF, which is difficult.

Both methods shine bright in their respective realms and cast beautiful colors on different apparel. Linko’s team of experts will help you make the right choice.

DTF gives life to various designs and ensures quality products with any fabric. But its print complexity is what differentiates it and makes it superior.

On the other hand, DTG limits itself to natural fibers only and can present itself as the first option for on-demand production.

To look for the perfect print, the contrast between DTG and DTF offers a series of choices for entrepreneurs. If you’re undecided, drop us a message for a free quote and guidance.